3D Printer Project: Six Handy Hand Tools to Print at Home

Put your 3D printer to work with these portable tools you can print on demand.Maker Projects

Photo: Dan Ackerman

There's nothing more frustrating than working on a project, from a desktop PC build to a Gunpla model, only to discover you're missing a tool needed to finish the job. Fortunately, as long as you have a 3D printer nearby, many solutions are just an hour or two of printing time and a few grams of filament away.

I recently printed a handful of clever, well-designed, pocket-sized backup tools that have already been put to use on my workbench, especially when I can't find something or just need a smaller version to fit into a tight space.

Photo: Dan Ackerman

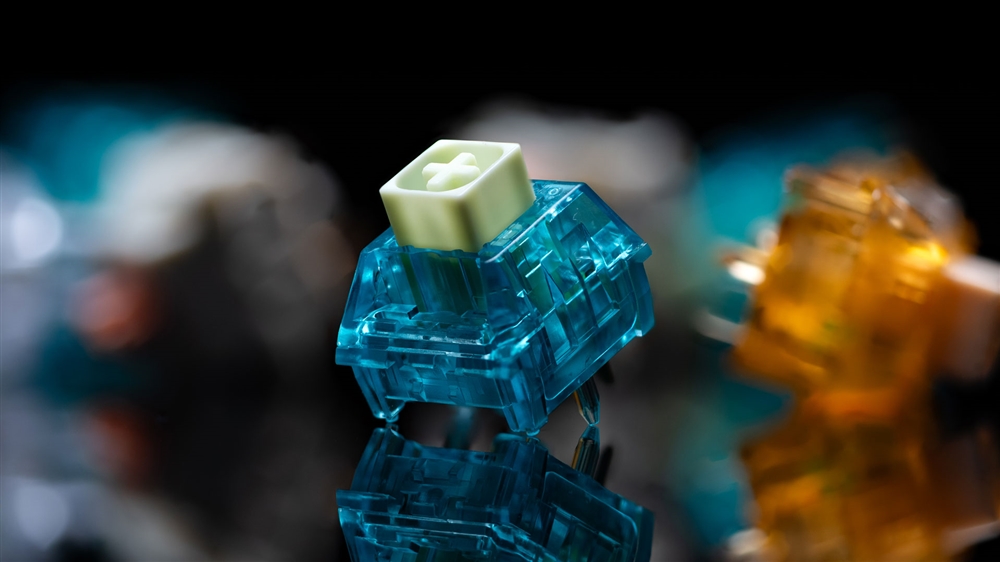

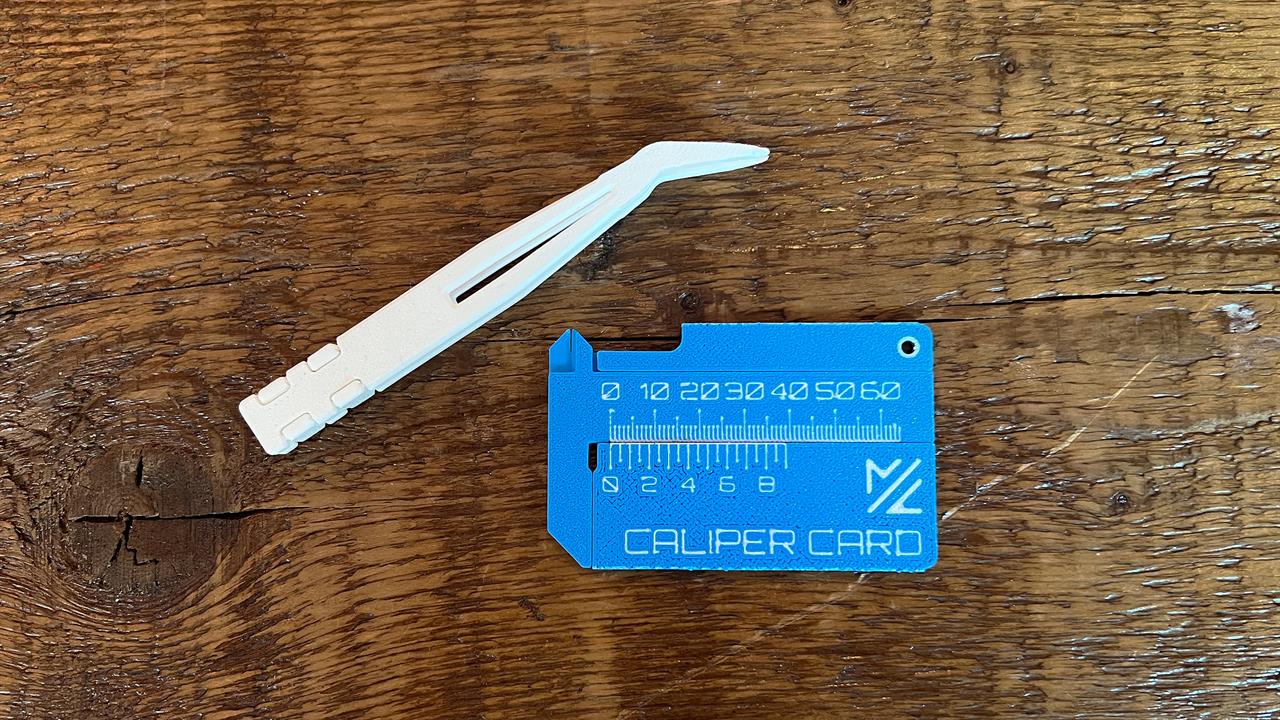

Calipers and tweezers

I use calipers way more often than I ever thought I would, for everything from measuring the exact dimensions of a phone case to measuring the size of a jar opening for a 3D-printed candy machine (one of my upcoming projects).

Typically I use a big digital model like this, but sometimes that's overkill, and it's easier to use this 3D-printed Vernier Caliper Card. It’s a functional caliper that fits in your wallet and prints in under an hour. It’s not going to replace a precision instrument, but for 90% of the quick measurements you might need to do, it’s perfect.

For more delicate tasks, like handling tiny electronic components, a good pair of precision tweezers is essential. These 3D-printed Precision Tweezers have a clever folding design that prints flat, and offers several variations with different points and angles. The fine points are good enough for all but the smallest screws, and the they're not so sharp that have to worry about accidentally poking yourself in the hand...

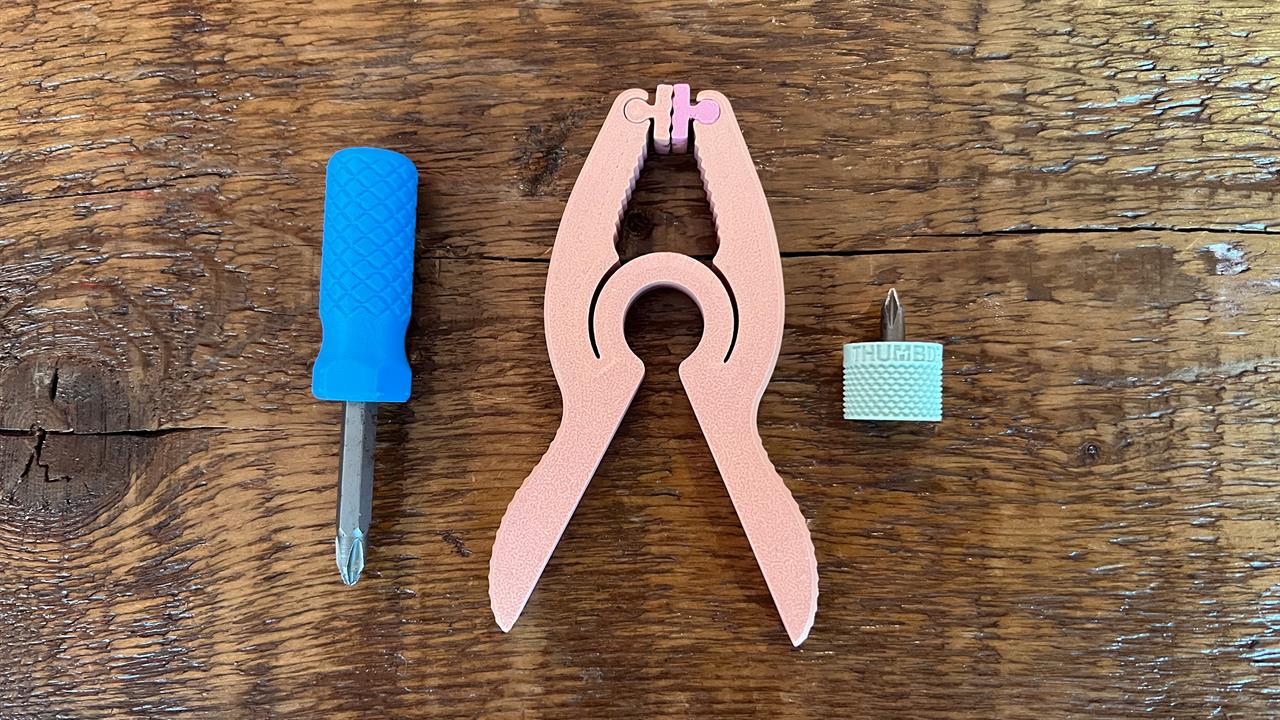

Clamps and drivers

This Print-in-Place Clamp is a single piece that comes off the print bed almost ready to use. PETG would make for a sturdier model with a stronger internal spring, but even a basic PLA print is good enough for simple jobs.

For all the screwdriver bits that litter my toolbox, it's handy to have some very small, portable drivers that I can use in a pinch. For example, this Super Mini Bit Tool, which is a tiny handle that accepts standard 1/4-inch hex bits. It prints fast, has a good grip, and is sturdy enough, even when printed in basic PLA.

For a very small-sized version, this ThumbDrive Micro works in a pinch and is just 15mm in diameter and 12mm thick, making it perfect to keep in your bag on the go, for just-in-case screwdriver emergencies. (What, you don't have those?)

Photo: Dan Ackerman

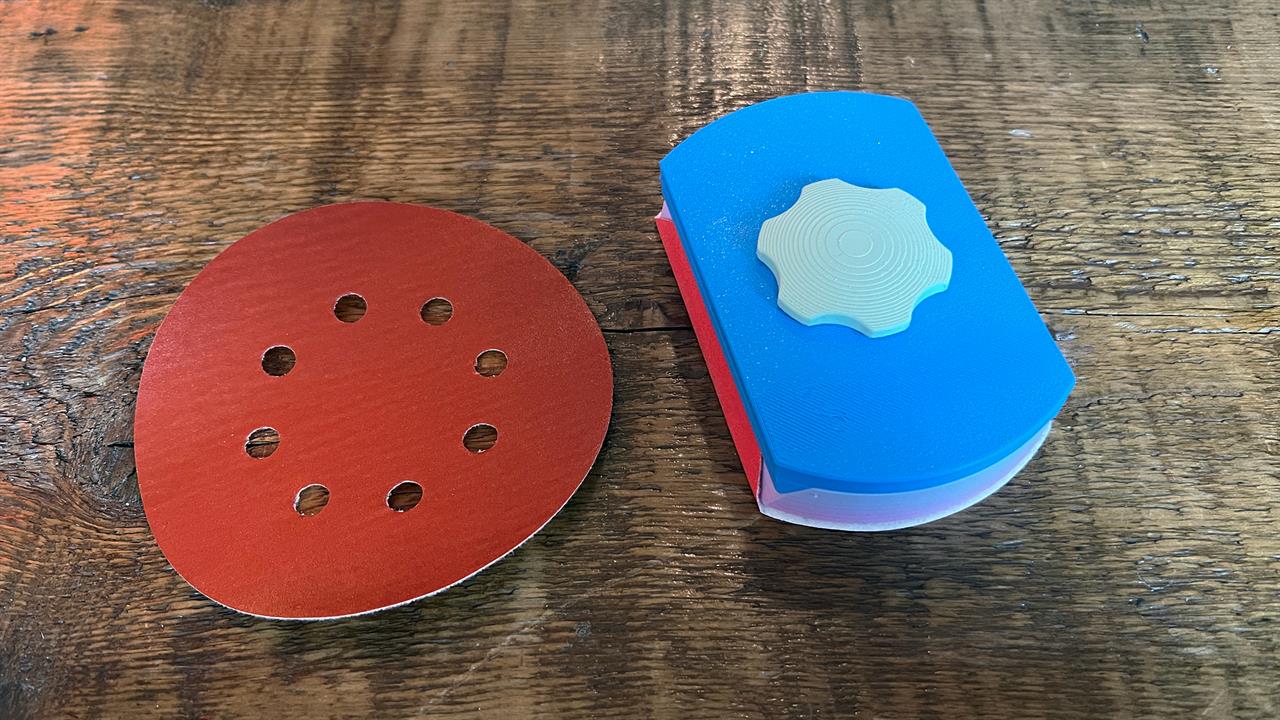

A well-rounded sanding block

I've got a lot of sanding discs for my orbital sander, but only a few sanding blocks. So naturally, I jumped at a chance to reuse those discs for regular hand-sanding and finishing. This ergonomic Sanding Block is one of the only tools like this I've found for using standard 5-inch hook-and-loop sanding discs and I especially liked the simple printed screw that holds the two parts together.

These are all relatively small and simple prints that should work on most printers, but I used a Bambu A1 and Inland PLA. Printing your own tools isn't just a gimmick or novelty, it's a way to make sure you have the exact right tool for the right job, and beats a last-minute emergency run to the hardware store.

Read more: 3D Printers and Maker Projects

- How to Design and 3D Print a Custom Phone Charging Dock

- Six 3D Prints to Spruce Up Your Garden

- See the Top-Rated 3D Printers at Micro Center

- This 3D-Printed Case Turns Your M4 Mac Mini into a Mac Pro Lookalike

- Insanely Useful Card Kits to 3D Print

- Supercharge Your Stanley with These 3D Printed Accessories

- We 3D-Printed a Guitar, and You Can Too

- FDM vs. Resin 3D Printing: Which is Right for You?

Micro Center Editor-in-Chief Dan Ackerman is a veteran tech reporter and has served as Editor-in-Chief of Gizmodo and Editorial Director at CNET. He's been testing and reviewing laptops and other consumer tech for almost 20 years and is the author of The Tetris Effect, a Cold War history of the world's most influential video game. Contact Dan at dackerman@microcenter.com.