FDM vs. Resin 3D Printing: Which is Right for You?

Resin and FDM printing both have their uses, but which should you use for your project?Maker Projects

If you've been following our previous articles, you're likely familiar with FDM and resin 3D printing (check out this article for a more in-depth explanation of the differences). But how do you decide which method suits your specific project needs? In this article, we'll explore the strengths and weaknesses of each process to help you make an informed decision. Whether you want to create detailed miniatures or functional parts, we've got you covered.

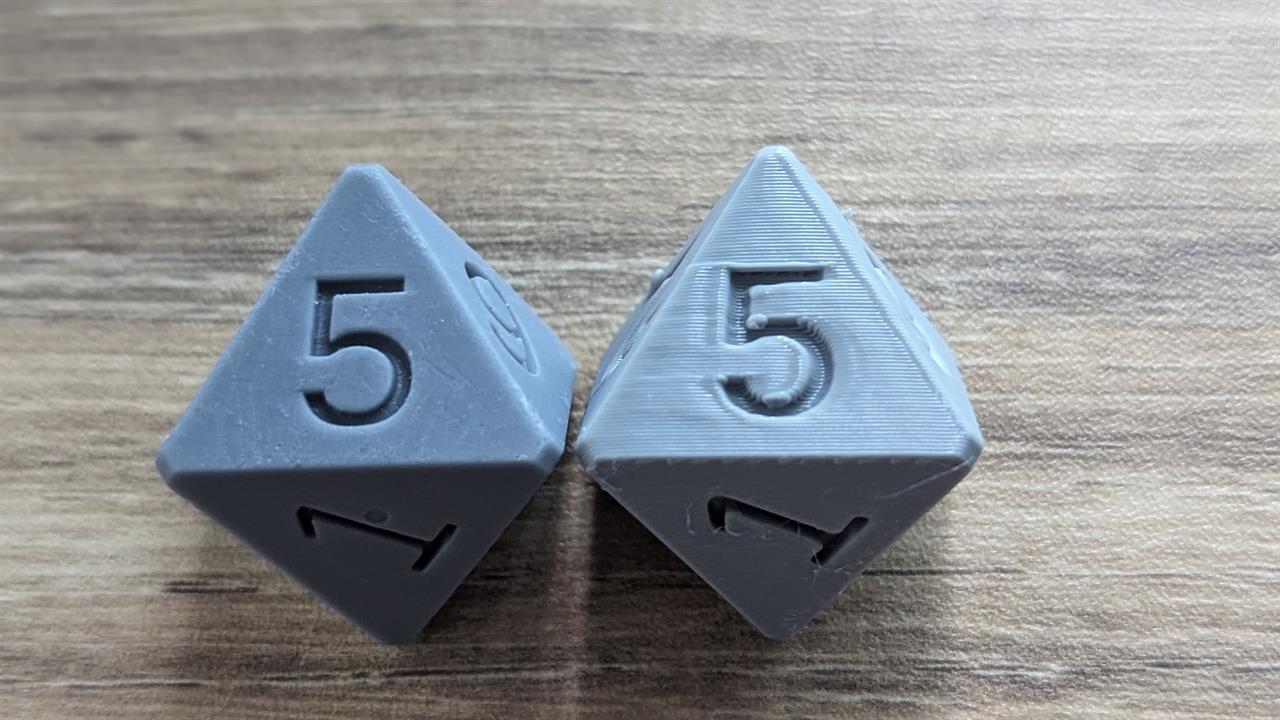

Left: Resin. Right: FDM Photo: Micro Center

Left: Resin. Right: FDM Photo: Micro Center Differences Between FDM and Resin 3D Printing

When choosing between FDM and resin 3D printing, it's essential to consider the specific needs of the project. Each method has its strengths, making them suitable for different types of prints.

Print Quality and Detail:

- FDM: Produces good quality prints with visible layer lines, making it best for functional parts and larger models.

- Resin: Excels in producing high-detail, smooth surface finishes, ideal for intricate and finely detailed models.

Print Speed:

- FDM: Generally faster for larger models and functional parts.

- Resin: Slightly slower due to the curing process, it offers superior detail for small parts and often fewer failed prints.

Material Costs:

- FDM: Typically has lower filament costs, making it more budget-friendly.

- Resin: While the material costs are higher, the investment is worthwhile for the high-quality, detailed prints it produces.

Post-Processing:

- FDM: Involves minimal post-processing, usually just removing supports and light sanding.

- Resin: Requires cleaning and curing. With the right tools and setup, this process becomes straightforward and manageable, offering stunning results.

Ease of Use:

- FDM: Known for its user-friendly setup and maintenance, it is an excellent choice for beginners.

- Resin: Involves a few additional steps but quickly becomes routine. The rewarding results in terms of detail and finish make the extra steps worthwhile.

Safety and Workspace:

- FDM: Requires minimal safety precautions and can be used in most indoor environments with good ventilation.

- Resin: Needs proper ventilation and safety gear (gloves, masks) due to resin fumes and chemicals. With the appropriate setup, safety measures are easy to follow.

Both FDM and resin 3D printing offer unique advantages. FDM is ideal for functional parts and larger models, while resin printing excels in detail and finish. Each method provides a rewarding experience, and choosing the right one depends on your project's specific needs.

FAQs for New Hobbyists

What kind of projects are best suited for FDM?

- FDM: Ideal for functional parts, prototypes, and larger models. Great for educational purposes and hobby projects where durability and size matter.

What kind of projects are best suited for resin printing?

- Resin: Perfect for detailed miniatures, figurines, jewelry, and projects requiring fine detail and smooth finishes. Resin printing excels in creating intricate and high-quality models.

How much maintenance do each of these printers require?

- FDM: Requires regular nozzle cleaning, bed leveling, and occasional part replacement (e.g., nozzles, belts).

- Resin: Clean the vat and build platform after each print, replace FEP films periodically, and carefully handle resin. With a proper routine, maintenance becomes straightforward.

Are there any health or safety concerns?

- FDM: Generally safe with minimal ventilation required. Basic precautions include avoiding burns from the hot end and heated bed.

- Resin: Requires proper ventilation and safety gear (gloves, masks) due to potential exposure to resin fumes and chemicals. Proper disposal of resin waste is also necessary.

We hope to clarify any concerns by addressing these common questions and help you decide which 3D printing method suits you. Both FDM and resin printing offer unique benefits, and trying both can enhance your 3D printing experience.

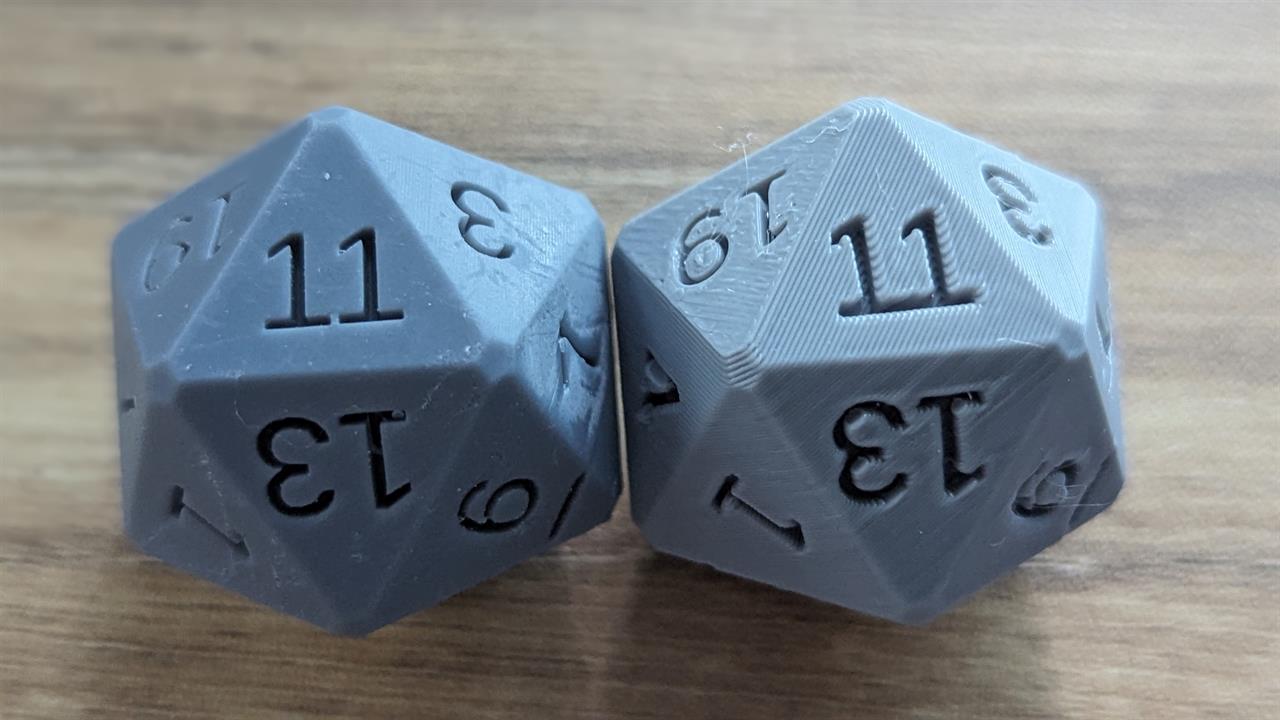

Left: Resin. Right: FDM. Photo: Micro Center

Left: Resin. Right: FDM. Photo: Micro Center Whether you prioritize ease of use, budget, or high-quality detail, understanding the strengths of each method will help you choose the best one for your specific needs. Both methods are rewarding and can enhance your 3D printing journey.

You can always make the easiest choice and use both!