Choosing the Best Supports for your 3D Print

There are a lot of 3D printing supports - here's how to pick the best one for your print!Maker Projects

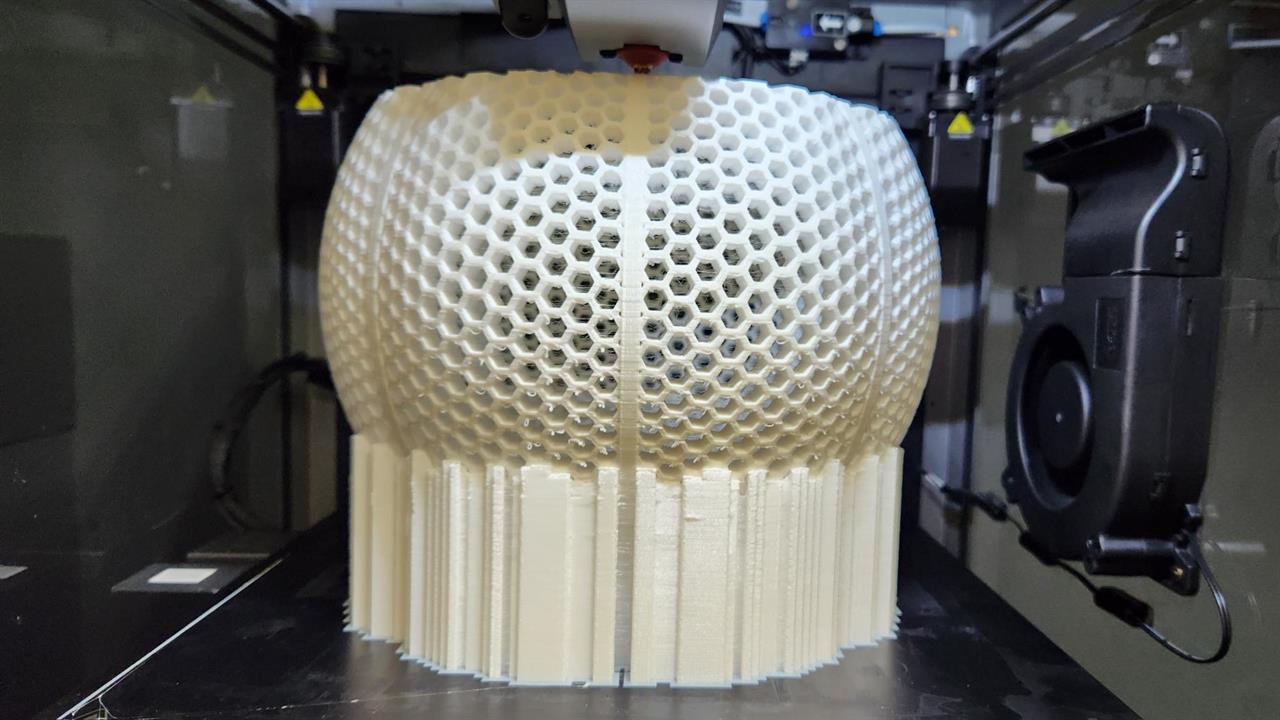

The world of 3D printing is constantly evolving, and understanding support structures is crucial to being successful. When creating objects with 3D printing, one of the most critical decisions is using slicer-generated supports or designer-integrated support structures. In this article, we explore both approaches and offer a comparison to help you make the best choice for your 3D printing projects. We also highlight a five-point workflow for minimizing the need for support structures, making the journey from concept to creation smoother.

Let's analyze the key aspects of each to help you decide.

Slicer-Generated Supports: Slicing software automatically generates these based on the model's geometry and overhang angles. They are designed for easy removal and minimal material usage while providing adequate support.

- Pros:

- User-friendly: Requires minimal intervention from the user, making it ideal for beginners.

- Versatility: Adaptable to a wide range of geometries without redesigning the model.

- Cons:

- Potential for waste: This can sometimes lead to excessive use of the material.

- Post-processing: Often requires significant cleanup, which can affect the surface quality of the print.

Designer-Integrated Supports: These supports are intentionally incorporated into the model by the designer, taking into account the specific needs and limitations of the printing process.

- Pros:

- Precision: Tailored to the model, reducing waste and offering better support.

- Reduced cleanup: Designed to break away cleanly, minimizing post-processing work.

- Cons:

- Time-consuming: Requires additional design time and expertise.

- Less flexibility: Modifying the model means redesigning the supports as well.

Optimized Design Guide

Embarking on the quest to minimize the need for support without compromising on complexity or aesthetics can seem daunting. However, with a strategic approach, it's entirely achievable. Here's a five-point workflow to guide your design process:

Understand Overhangs and Bridges:

- Begin by familiarizing yourself with the limits of overhangs and bridges your printer can handle without support. This knowledge will be pivotal in designing more printer-friendly models.

Optimize Orientation:

- Experiment with the orientation of your model in the slicing software. Sometimes, a slight adjustment can significantly reduce the need for support.

Incorporate Features to Reduce Overhangs:

- Design techniques such as adding fillets, chamfers, or changing geometric features can effectively reduce overhangs, negating the need for support.

Utilize Cantilevers and Arches:

- Incorporate architectural principles like cantilevers and arches into your designs. These features can span gaps without the need for support beneath them.

Test and Iterate:

- The final step is testing your designs and iterating based on the results. Each failure is a stepping stone to mastering support-free printing.

Bridging the Gap: A Comparative Analysis

Considering several factors before deciding whether to use slicer-generated or designer-integrated supports in 3D printing is essential. These factors include the intended usage of the printed object, the design's complexity, and the user's proficiency in design and post-processing.

For hobbyists just starting with 3D printing, slicer-generated supports can be a good starting point since they are easier to use and more accessible.

Professionals and enthusiasts may prefer designer-integrated supports due to their greater precision and efficiency, which can lead to higher quality standards and reduced material costs.

Ultimately, the decision to use slicer-generated or designer-integrated supports depends on balancing the printed object's time, material costs, and desired finish. A hybrid approach, where both methods are used depending on the specific requirements of each print job, can often yield the best results.

It's your Turn to Innovate

As we end our exploration of 3D printing supports, we encourage you to embark on your journey of discovery. Try experimenting with slicer-generated and designer-integrated supports. Challenge yourself to create 3D prints that don't require support by taking advantage of the optimized workflow as your guide.

Comment on This Post

See More Blog Categories

Recent Posts

This Week in AI: OpenAI Promises GPT-5 Changes

For Aug. 15, 2025: Perplexity bids for Google Chrome, Google adds "Create" tab to Photos, more impacts from AI energy needs, Elon Musk goes after Apple over OpenAI, companies still searching for AI profits.

Continue Reading About This Week in AI: OpenAI Promises GPT-5 Changes