Speed Meets Quality: Comparing High-Speed and Traditional Filament

High-Speed PLA delivers quicker prints without sacrificing quality, but how does it stack up to traditional PLA?Maker Projects

The progression from standard PLA to its high-speed variants marks a significant 3D printing material technology shift. Makers prize standard PLA for its ease of printing and low melting point. However, as 3D printers have evolved to offer faster print speeds and more complex capabilities, standard PLA's slower printing speeds and lower thermal resistance have limited its application in more demanding projects.

In response to these advancements, high-speed PLA variants have been developed, including Inland High-Speed PLA and Inland High-Speed Silk PLA. This evolution reflects the 3D printing industry's response to the need for materials that can keep pace with the technological advancements of printers. By offering a solution that combines the benefits of PLA with the performance characteristics necessary for advanced printing tasks, high-speed PLA variants represent a significant milestone in the development of 3D printing materials.

Photo: Micro Center

Photo: Micro Center To test these claims, we put both high-speed PLA variants and standard PLA through practical tests, including print speed, quality, and material properties, using a benchy model printed at different speeds.

Optimized Printing Parameters

Optimizing printing parameters is crucial for maximizing the performance of Inland High-Speed PLA and Silk PLA, distinguishing these materials from standard PLA. While standard PLA typically prints at temperatures ranging from 190°C to 220°C with speeds of 40-60mm/s, designers have optimized high-speed variants to operate effectively at higher settings.

Inland High-Speed PLA and Inland High-Speed Silk PLA require a nozzle temperature of 210°C to 230°C to facilitate a smooth material flow at increased speeds. This higher temperature range is essential for maintaining prints' integrity at speeds exceeding 300mm/s, significantly reducing printing time for large projects or batch production.

Print speed, a critical parameter, is where high-speed variants shine. Capable of printing efficiently at speeds beyond 300mm/s, these materials substantially improve over standard PLA, enabling faster project completion without sacrificing detail or structural integrity.

Performance Comparison Results

Our performance comparison between Inland High-Speed PLA, Inland High-Speed Silk PLA, and standard Inland PLA filaments focused on several key areas: print speed, quality, layer adhesion, and post-processing capabilities. Here are the summarized results based on the practical tests conducted with the benchy model at different print speeds:

Print Speed:

High-speed PLA variants demonstrated a significant reduction in print times, with the ability to maintain speeds beyond 300mm/s without compromising the integrity of the print. Standard PLA, while capable of achieving satisfactory results at standard speeds (40-60mm/s), showed noticeable declines in quality at higher speeds. This is likely due to the optimal flow rate being lower for standard PLA filaments.

Print Quality:

Inland High-Speed PLA and Silk PLA maintained high print quality at accelerated speeds, 600mm/s, producing crisp details and smooth surfaces. Standard PLA struggled with fine details and surface smoothness at increased speeds, indicating its limitations for rapid printing applications.

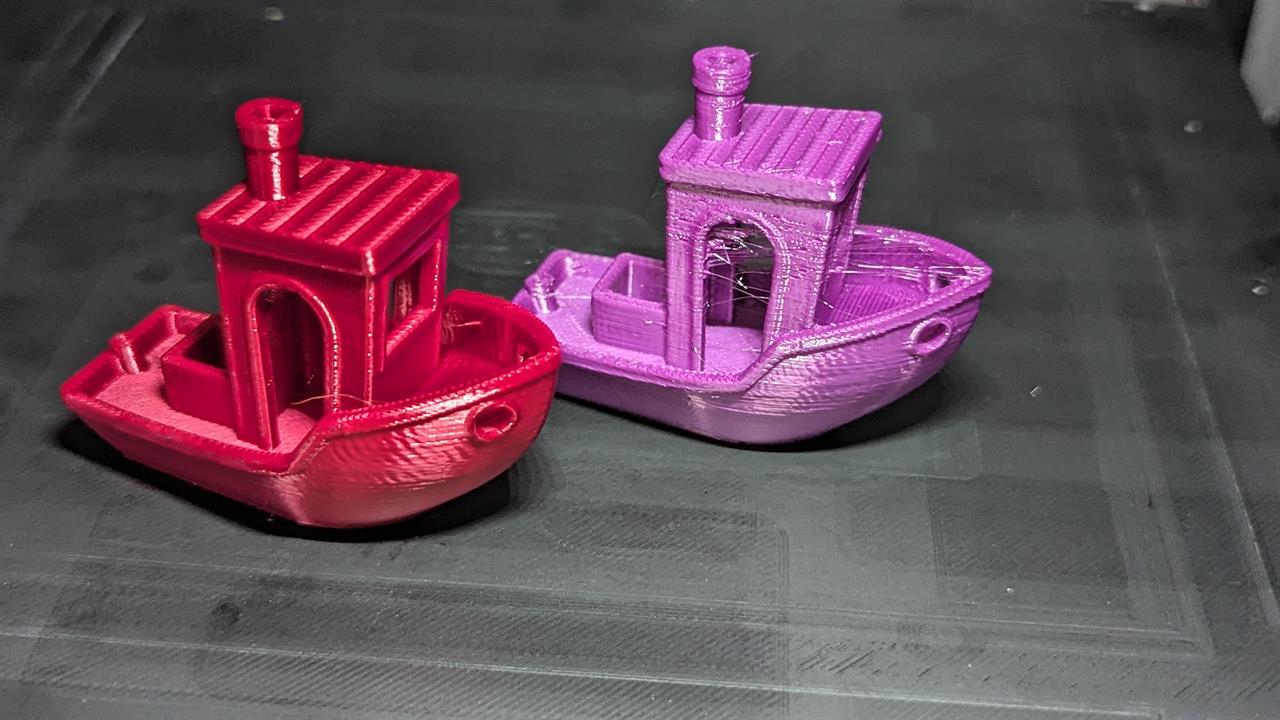

Left - High Speed PLA, Right - Standard PLA. Photo: Micro Center

Left - High Speed PLA, Right - Standard PLA. Photo: Micro Center Layer Adhesion and Strength:

High-speed PLA variants exhibited superior layer adhesion and overall strength compared to standard PLA, making them more suitable for functional parts that require durability.

Post-Processing Capability:

Both high-speed and standard PLA filaments were amenable to post-processing techniques like sanding and painting. However, the High-speed PLA variants stood out due to fewer surface imperfections that would require additional processing.

Filament Consistency and Reliability:

During the tests, Inland High-Speed PLA and Silk PLA demonstrated consistent performance with fewer printing issues like clogging or stringing. Standard PLA was generally reliable at standard speeds but encountered more problems when pushed to higher speeds.

Left - High Speed Silk PLA, Right - Standard Silk PLA. Photo: Micro Center

Left - High Speed Silk PLA, Right - Standard Silk PLA. Photo: Micro Center These results highlight the advantages of high-speed PLA variants in scenarios requiring rapid production, complex geometries, or functional part fabrication. Inland High-Speed PLA and Silk PLA offer the benefits of standard PLA and enhance print speed and material properties, making them a valuable choice for advanced 3D printing projects.

As 3D printing advances, developing materials like Inland High-Speed PLA and High-Speed Silk PLA will enable creators to bring their visions to life more efficiently and effectively. For enthusiasts and professionals alike, these materials unlock new possibilities and push the boundaries of what they can achieve with 3D printing technology.